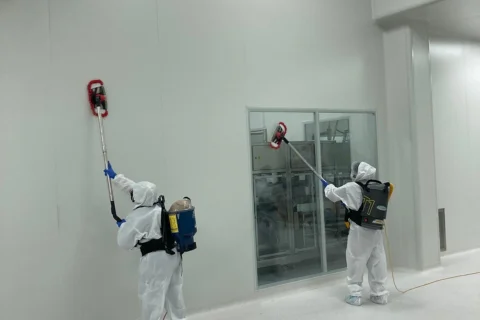

Pre-validation clean with HEPA vacuums

Scissor lift is required to access the ceiling in this pre-validation clean.

Floor is vacuumed and mopped in this pre-validation clean.

Description

BACS pre-validation cleaning services for cleanrooms are available nationwide including Sydney, Melbourne, Perth, Canberra, Brisbane, Adelaide, Hobart and Darwin as well as most regional areas.

Once a cleanroom is built, the HVAC system is operating and all equipment is installed, a meticulous initial clean is required prior to validation and use. Periodically thereafter, major cleaning preceding recertification is necessary to maintain compliance with regulatory bodies such as the Therapeutic Goods Administration (TGA). Because viable and non-viable contaminants in a cleanroom are often invisible to the naked eye, people who thoroughly clean and disinfect critical environments require specialised training, equipment and technique. Effective contamination control means eliminating existing contaminants without introducing new ones from cleaning personnel or their supplies and equipment.

Features

- BACS pre-validation cleaning removes physical (such as dust, fibres and metallic particles), chemical (such as cleaning agent residue and cross-contamination) and microbiological contamination from a cleanroom to meet required standards.

- BACS can either follow your existing SOPs or, in the case of a new facility, review your proposed cleaning plan and offer suggestions on how best to achieve the cleanliness target.

- Pre-validation cleaning is a comprehensive multi-stage process that concentrates on all top, bottom and vertical cleanroom surfaces including ceilings, walls, floors, benches and fittings to remove contaminants and where necessary, disinfect.

- Depending on your preference, BACS will either use your approved and dedicated cleaning products and equipment or can supply our own.

- BACS-supplied equipment is used only in cleanrooms, is stored in the BACS cleanroom and is carefully wiped down and prepared prior to use in your facility to avoid cross-contamination.

- BACS cleaners review site-specific procedures, gown up appropriately, work in a systematic way, complete compliance paperwork and are properly supervised to achieve the desired results.

Benefits

- BACS can supply trained cleanroom cleaners and equipment for periodic major cleans, saving you from sourcing and training extra labour, outfitting them with the proper cleaning gear and supervising their performance.

- BACS cleaning expertise enhances your ability to pass certification the first time.

- BACS can advise you on selecting the appropriate cleaning validation kits, sampling swabs, wipers, mops, adhesive-coated contamination control mats and other cleaning equipment and consumables for your class of cleanroom.

- To maintain compliance and keep contamination under control, BACS can schedule a routine cleaning service as part of your overall facility maintenance plan.