Site Information

Indoor Air Particle Testing & Reporting

LIKE A REPORT CARD ON YOUR DATA CENTRE AIR QUALITY

HOW DO YOU TELL IF YOU HAVE A PROBLEM?

Progressive data centre operators have recognised the value of measuring their air cleanliness against an international benchmark borrowed from the cleanroom industry.

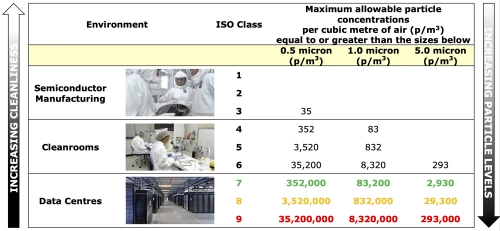

The ISO 14644-1:2015 standard contains air sampling guidelines that provide at least 95% confidence that at least 90% of a room does not exceed the ISO Class limit. Rooms are categorised into ISO Classes from 1 (the cleanest) to 9 (the least clean). Data centres and other IT environ�ments are typically between ISO Class 7 to 9.

Being able to show a data hall meets a certain ISO Class gives data centre facility managers proof that their facility is suitable to house critical operating equipment.

Fig 1: Indoor air particle testing in a data centre

Fig 1: Indoor air particle testing in a data centre

Fig 2: ISO Classification

Fig 2: ISO Classification

WHY YOU SHOULD BE CONCERNED?

Airborne contamination in your data centre can significantly degrade device performance. Miniscule particles which remain suspended in air are drawn into operating equipment by device cooling fans. Once inside, particles can block filters and accumulate on fans, leading to overheating. Abrasive dust can cause mechanical malfunctions. Depending on the source, dust particles can also be corrosive and conductive, damaging motherboards and short-circuiting power supplies.

Larger particles (or clusters of smaller particles) in the room pose less of a threat because they eventually settle on a surface and are vacuumed up or wiped away during routine cleaning.

HOW TO MINIMISE YOUR RISK

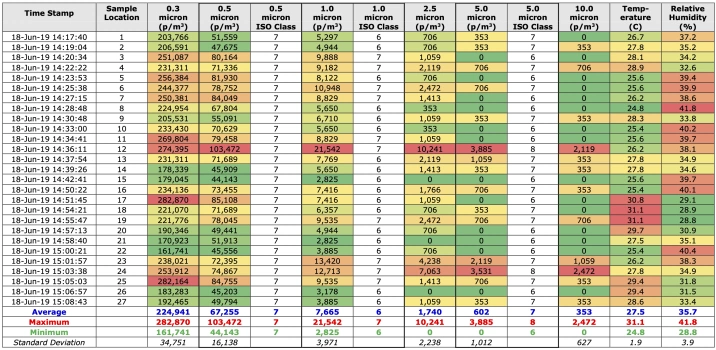

Arrange for your data halls to be tested according to the ISO 14644-1 standard. Don’t just stop at seeing what ISO Class they achieve. Make sure you get a comprehensive report which shows where the highest and lowest particle levels are located in each room.

By systematically examining these areas, it’s possible for you to reduce the overall number of particles in the room and therefore improve the ISO Clas

- Evaluate areas with elevated particle levels to find potential contamination sources.

- Avoid storing unnecessary items in the room. If you must, remove any cardboard packaging and transfer to plastic storage containers.

- Check entrance doors and other room penetrations to make sure they are properly sealed.

- Determine whether particles are concentrating in certain sections of the room and increase or better direct air flow.

- Replace all air filters on a regular basis so they don’t become overloaded or develop holes which allow particles to enter the room.

- Have a regular cleaning schedule in place and adjust depending on what’s happening in or near the room (construction or maintenance activities, increased traffic entering room, etc.)

- Keep an ESD-safe vacuum cleaner onsite and easily accessible so technicians can clean inside server racks when they complete their work.

- Verify whether particle levels are increasing over time by testing at regular intervals.

- Implement and document corrective actions to track their effectiveness.

- Review and update your monitoring plan on a yearly basis

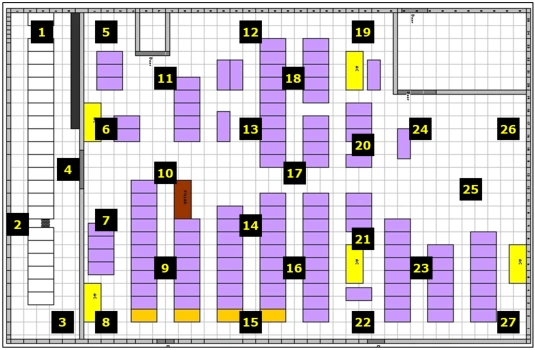

Fig 3. Indoor air particle room sampling map

Fig 3. Indoor air particle room sampling map

Fig 4. Indoor air particle testing report

Fig 4. Indoor air particle testing report